The German carmaker has been known to go heavy on the carbon fibre treatment in some of its higher-end and performance models, with everything from interior trim to lighter weight exterior parts.

BMW was an early adopter of using carbon fibre on a larger scale too, with its i3 and i8 featuring large amounts of the material.

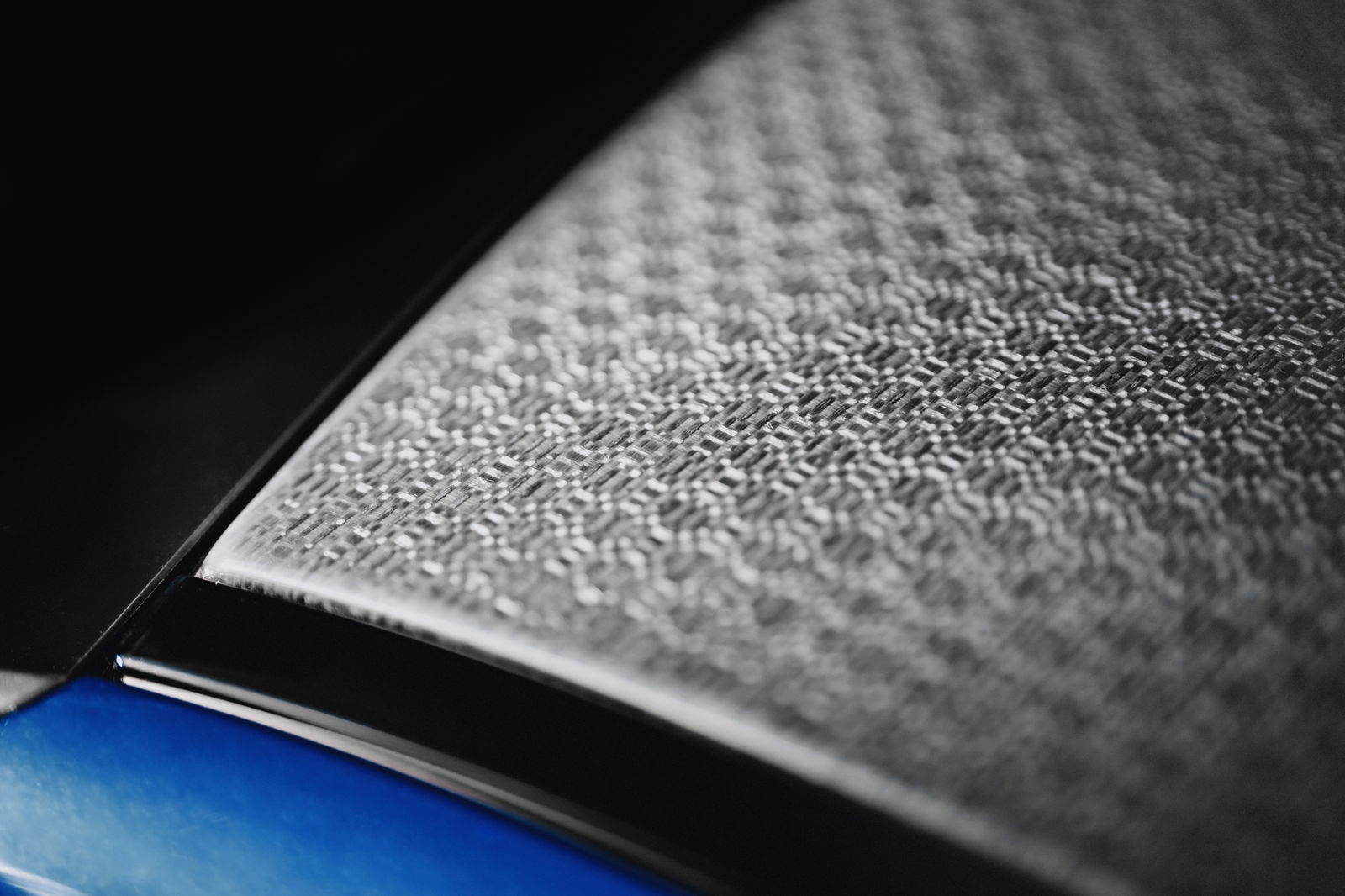

However, it’s recently been busy developing natural fibre composites, which it now says have “reached series maturity” – short for ready for production. Developed in conjunction with Swiss firm Bcomp, the flax-based lightweight components are not only as strong as carbon fibre, but also environmentally cleaner to make.

BMW claims using natural rather than carbon fibre composites in its next-generation models could lead to a CO₂e-reduction of about 40 per cent, encompassing production and the end of the material’s life.

As with many automotive innovations, the natural fibre composites have been used first in motorsport, with BMW M rolling out the materials in Formula E back in 2019, before replacing the carbon fibre reinforced plastic (CFRP) parts on its BMW M4 DTM and GT4 racers.

“Natural fibre composites are a vital element of innovative lightweight solutions in motorsport, allowing for a reduction in CO₂e emissions in the manufacturing process,” said BMW M CEO, Frank van Meel.

“Natural fibre is an innovation that perfectly exemplifies BMW M’s claim ‘Born on the racetrack. Made for the streets’. This is why we are delighted to confirm the series maturity of these materials, a breakthrough we achieved with our official BMW M Motorsport partner Bcomp. We are now looking forward to the use of these materials in future BMW M product ranges.”

While we can not only expect more future BMW models such as the Neue Klasse-based M3s to adopt the new composites, the car industry as a whole could find alternatives to carbon fibre, given the automotive industry consumes about 20 per cent of it.

Discussion about this post